Introduction to Repmold

Repmold is quickly becoming one of the most exciting buzzwords in the world of modern manufacturing and product innovation. But what exactly makes it special? In simple terms, Repmold represents the fusion of replication and molding, a concept that brings together the precision of advanced fabrication with the adaptability of smart design.

Imagine being able to reproduce high-quality products, parts, or systems faster, cheaper, and more sustainably than ever before. That’s what Repmold technology promises.

Across industries from automotive to aerospace, Repmold is helping engineers and creators reshape how things are made, customized, and scaled. The idea is not just about copying; it’s about refining the copy until it becomes smarter, more efficient, and more adaptable.

Overview and Importance in Modern Industry

In today’s fast-moving economy, businesses can’t afford long production cycles. Repmold offers a practical solution by allowing rapid prototyping and scalable manufacturing without sacrificing accuracy.

Companies use Repmold to shorten time-to-market, reduce material waste, and create product lines that respond faster to market demand. It’s not just a technology; it’s a mindset shift in how we think about making things.

Why the Term “Repmold” Is Gaining Popularity

As industries chase digital transformation, “Repmold” has become a catchword for smart replication systems.

Its appeal lies in its simplicity: replicate excellence, mold innovation. From start-ups to Fortune 500 firms, everyone wants a piece of it because it blends engineering, software, and sustainability into one unified approach.

What Is Repmold?

Repmold, at its core, is both a process and a philosophy. Technically, it refers to the replication of a model, design, or prototype through molding or digital duplication methods such as additive manufacturing or 3D printing.

Conceptually, it embodies innovation that scales, making high-quality replication accessible without diluting originality. Whether used to reproduce machine parts or digital assets, Repmold technology bridges the gap between creativity and manufacturability.

Definition and Core Concept

Repmold combines replication, the act of recreating something with accuracy, with molding, the art of shaping new forms. This synergy allows businesses to recreate designs that maintain structural integrity while improving efficiency. In essence, it’s about building a smarter clone, not just a copy.

Literal vs Metaphorical Interpretations

While manufacturers use Repmold literally for physical production, digital innovators apply it metaphorically as in replicating success models or workflows. It’s both tangible and strategic: a process that molds not only materials but also mindsets.

Origin and Etymology of Repmold

The word Repmold stems from two simple ideas: “Replicate” and “Mold.” Together, they signal a new manufacturing paradigm, one where precision meets adaptability. Historically, the concept can be traced back to industrial molding and duplication processes that evolved alongside the rise of automation.

However, Repmold as a term started gaining traction when advanced 3D printing and AI-assisted design entered the mainstream.

Historical Industry Roots

From early die-casting in the 19th century to today’s automated robotic molding systems, replication has always been central to manufacturing. Repmold builds on this legacy, integrating digital data, machine learning, and real-time optimization into age-old molding methods.

Evolution from Traditional Molding and Replication

Traditional molding was about form and structure. Repmold elevates that by making the process dynamic and data-driven. Instead of repeating the same mold endlessly, modern systems analyze performance and adapt future molds automatically.

Symbolic Meaning of “Rep + Mold”

On a symbolic level, “Rep” reflects scalability and consistency, while “Mold” embodies creativity and transformation. The combination represents a philosophy of iterative improvement, a loop where every replica leads to a better mold for the next cycle.

Core Principles Behind Repmold

Repmold technology thrives on three guiding principles: precision, efficiency, and adaptability. Each project or product iteration aims to be more refined than the last. Unlike traditional molding, which focuses only on duplication,

Repmold emphasizes intelligent improvement. The integration of sensors, AI, and digital twins ensures that every mold learns from its predecessor, an approach that turns production into a continuous feedback loop.

The Science of Replication and Design

Repmold leverages data analytics to perfect replication accuracy. Every measurement, texture, and tolerance is digitally recorded, ensuring near-zero deviation between the prototype and final product. It’s manufacturing guided by metrics, not just intuition.

Relationship with Innovation and Adaptability

What makes Repmold revolutionary is its ability to evolve. A Repmold system can adjust designs automatically when materials change or user feedback shifts, making it ideal for industries that demand customization at scale.

You Might also Like“What is Konversky?“

How Repmold Works in Practice

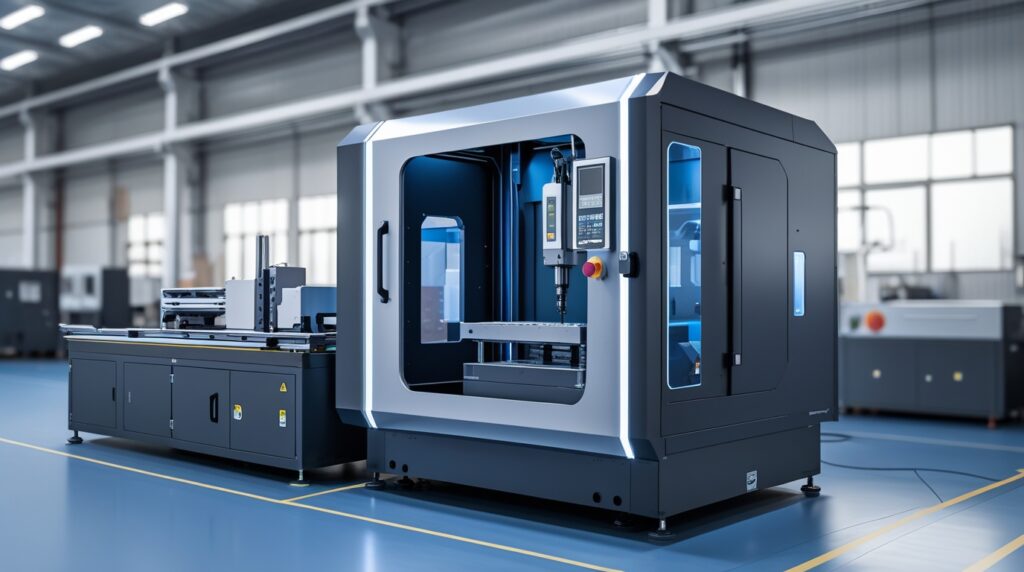

The working process of Repmold technology is surprisingly straightforward yet deeply innovative. It begins with a concept or digital design, which is converted into a physical or virtual mold.

Using 3D scanning, CAD modeling, and precision molding systems, the product is then replicated with minimal variation. Every iteration is analyzed in real-time, and improvements are fed back into the design cycle.

This self-optimizing loop is what separates Repmold from traditional molding. It doesn’t just produce; it evolves.

Process Flow and Typical Steps

A standard Repmold workflow follows these stages:

Concept & Design Phase – Designers create a digital model using CAD or 3D scanning.

Prototype & Mold Creation – The model is molded or printed using chosen materials.

Replication & Production – Multiple high-precision replicas are produced efficiently.

Quality Review & Feedback Loop – Data insights improve the next version automatically.

Tools, Frameworks, and Best Practices

Modern Repmold systems use AI-driven analytics, automated robotics, and digital twins to predict flaws before production. Best practices include real-time calibration, material testing, and adaptive learning algorithms to ensure consistency at every stage.

Repmold in Manufacturing & Industrial Applications

Repmold’s biggest impact is visible in heavy manufacturing. From aerospace components that require micron-level accuracy to consumer goods that must be mass-produced quickly, Repmold makes precision replication scalable.

By combining digital design and physical production, it eliminates delays, reduces waste, and ensures repeatability, key factors for industries where consistency is king.

Injection Molding, Casting, and Replication Processes

Repmold enhances traditional methods like injection molding and casting by integrating smart sensors and digital feedback systems.

This hybrid model ensures every part matches exact design intent, even across large production runs.

3D Printing and Additive Manufacturing as Enablers

Additive manufacturing is a natural ally of Repmold. It allows molds and replicas to be created faster and with complex geometries that were once impossible, pushing the limits of what replication can achieve.

Industrial Case Example – Automotive, Aerospace, Consumer Goods

Automotive manufacturers use Repmold to replicate engine components; aerospace firms use it for lightweight, high-strength parts; and consumer brands use it for durable packaging and electronics. Across the board, the message is clear: Repmold is not the future, it’s already here.

Repmold in Product Design and Prototyping

If there’s one area where Repmold technology truly shines, it’s product design. Imagine turning a digital sketch into a tangible prototype in hours, not weeks.

Repmold makes that happen. By merging replication accuracy with design freedom, teams can now experiment faster, tweak instantly, and test efficiently. For designers, this isn’t just convenience; it’s liberation.

You no longer have to choose between creativity and manufacturability. Repmold bridges that gap by ensuring what you imagine can actually be produced, at scale, with precision.

Role in Rapid Prototyping and Iteration

Traditional prototyping often meant costly molds and time-consuming adjustments. With Repmold, designers can modify the digital model, rerun the replication, and see real-time results. The cycle is fast, data-driven, and flexible, the perfect environment for innovation.

Improving Precision & Cost Control

Every iteration through Repmold reduces the margin of error and saves resources. Since the system learns from prior prototypes, the cost per refinement drops significantly. Businesses love it because it means predictable expenses and consistent quality.

Repmold in Digital and Technology Domains

The digital world has its own form of molding and replication, think of software templates, automation scripts, or even AI-driven design patterns. Repmold technology takes these ideas further by connecting physical manufacturing with digital intelligence.

Smart sensors, IoT devices, and cloud-based analytics now monitor molds in real time, learning from every run. This fusion of digital data and industrial hardware transforms factories into self-correcting ecosystems where machines “know” how to improve production with minimal human intervention.

Software, Automation, and AI Integration

Modern Repmold systems often include embedded software powered by artificial intelligence. These platforms collect data, predict defects, and automatically adjust machine parameters. The result? Less downtime, fewer rejected parts, and a production line that thinks ahead.

Digital Twins and Virtual Replication

One of the most powerful innovations connected to Repmold is the use of digital twins, virtual copies of real-world molds and machines.

Engineers can simulate performance, stress-test components, and identify inefficiencies before physical production even begins. It’s like having a rehearsal before the main act, saving time and money while boosting reliability.

Repmold in Creative Industries (Art, Media & Design)

When we think of replication, art isn’t usually the first thing that comes to mind, yet Repmold is quietly transforming creative fields, too. Artists, filmmakers, and product designers are using it to reproduce detailed sculptures, props, and design prototypes with stunning precision.

Repmold helps creatives scale their vision without losing authenticity. It’s about preserving the soul of the original while expanding its reach. For media houses and art studios, Repmold technology is like having a bridge between craftsmanship and scalability.

How Artists and Designers Use Repmold

Artists use Repmold for reproducing installations, replicas of fragile artifacts, or creating limited-edition runs. For designers, it’s a shortcut to material testing and client visualization a way to transform ideas into tangible experiences quickly.

Balancing Originality and Reproduction

Critics often worry that replication kills originality. But Repmold challenges that assumption. It doesn’t replace creative genius; it amplifies it. By letting artists duplicate their ideas responsibly, it ensures innovation spreads without diluting the craft.

You Might also Like“What Is CHAS6D“

Repmold in Business Strategy and Branding

In the business world, efficiency isn’t just a technical goal; it’s a competitive advantage. Repmold fits right into this strategy by redefining how companies approach production, scalability, and customer satisfaction.

Think of it as a playbook for consistency: every unit, every part, every product looks and performs the same, no matter where it’s made. That reliability strengthens brand identity and trust. Moreover, the adaptability of Repmold means businesses can respond to market changes faster, without retooling entire facilities.

Process Optimization and Efficiency

Repmold simplifies production chains by automating repetitive steps and minimizing manual error. When data from each mold feeds into the next, performance improves across the board less waste, smoother workflows, higher ROI.

Repmold as a Business Model Innovation

More than just a manufacturing process, Repmold can reshape business models. Subscription-based production, on-demand manufacturing, and decentralized fabrication are all made possible when replication becomes digital, precise, and portable.

Key Benefits of Adopting Repmold

Businesses across industries are adopting Repmold technology because it delivers measurable, tangible benefits. The combination of data intelligence, precision molding, and automation allows companies to do more with less material waste, less downtime, and less cost.

But perhaps the greatest advantage lies in agility. With Repmold, enterprises can move from idea to execution faster than their competitors, maintaining quality while scaling operations globally. It’s a game-changer for any company serious about innovation.

Precision, Consistency, and Quality Control

Every mold and replica in a Repmold system is monitored digitally, ensuring microscopic consistency. Quality is built into the process, not just checked at the end, which means fewer recalls and higher customer trust.

Speed, Flexibility, and Cost-Efficiency

By merging digital design with automated replication, Repmold shortens production timelines dramatically. Businesses save time and operational costs while maintaining flexibility for design adjustments or customization.

Scalability and Customization Potential

Repmold thrives on adaptability. Once a successful mold is established, scaling production to thousands or even millions of units becomes effortless. And since molds can be digitally altered, customization no longer conflicts with mass production.

Major Challenges and Limitations

Of course, like any transformative technology, Repmold isn’t without its challenges. Implementing it requires upfront investment, skilled operators, and a cultural shift in how organizations view production.

For smaller companies, the cost of automation and AI integration can be intimidating. Moreover, because Repmold thrives on data, maintaining cybersecurity and quality control across networks becomes crucial.

Yet, despite these obstacles, the long-term payoff far outweighs the short-term hurdles, and early adopters are already proving that.

Risk of Over-Replication and Loss of Originality

When replication becomes too easy, there’s a temptation to copy rather than create. The key is using Repmold as a tool for enhancement, not imitation. Successful firms strike that balance by keeping innovation at the heart of every replication cycle.

Technical and Skill Barriers

Repmold systems demand knowledge in both digital modeling and machine operations. Training employees to manage AI-assisted molds, sensors, and real-time analytics is vital for smooth implementation.

Material and Supply Chain Constraints

Some advanced molds still depend on specialized materials that can be expensive or regionally limited. However, ongoing research into biodegradable and smart materials is steadily closing this gap.

Case Studies: Real-World Examples

The best way to understand Repmold’s power is by seeing it in action. In the automotive industry, manufacturers are using Repmold technology to replicate engine and interior components with pinpoint accuracy. Each cycle captures new data, helping them refine fuel-efficiency designs while cutting production waste.

In healthcare, companies use Repmold for prosthetics and surgical tools, ensuring every replica fits individual patient needs. And in construction, architects employ Repmold for modular housing systems, producing identical panels that save both time and cost. These cases show how Repmold turns theory into measurable performance.

Materials, Tools, and Technologies Used

Modern Repmold ecosystems rely on advanced materials such as lightweight alloys, reinforced polymers, and biodegradable composites. Smart sensors monitor heat, pressure, and viscosity in real time, while AI-driven control systems adjust settings automatically.

On the digital side, CAD/CAM software and 3D printing tools form the backbone of mold design and testing. The seamless interaction between these elements allows manufacturers to push the limits of innovation while maintaining efficiency.

Sustainability and Environmental Impact

Repmold contributes by reducing scrap rates and optimizing raw material use. Because molds are digitally simulated before production, fewer test runs are needed, translating directly into less waste.

Additionally, the adoption of recyclable and bio-based materials in Repmold systems aligns with global carbon-reduction goals. By promoting circular-economy principles, Repmold isn’t just building products; it’s building a cleaner future.

Market Trends and Global Growth

Global demand for smart manufacturing and additive production is accelerating, and Repmold sits right at that intersection.

North America and Europe lead in adoption due to advanced automation infrastructures, while Asia’s rapid industrial growth makes it the fastest-expanding region for Repmold applications.

Analysts predict double-digit market growth through the next decade, fueled by the shift toward mass customization and data-driven manufacturing strategies.

Future Possibilities and Innovation

The next generation of Repmold will be even more intelligent. Expect AI-powered predictive molds, nano-structured materials, and IoT-connected fabrication lines capable of self-repair and remote optimization.

As industries experiment with space-grade materials and extreme-environment manufacturing, Repmold will evolve from a production method into an ecosystem one where machines learn, adapt, and create alongside humans.

How to Integrate Repmold into Your Business

Integrating Repmold starts with a readiness audit: assess your digital capabilities, workforce skills, and product-line suitability. Begin with small pilot projects, gather feedback, and scale gradually.

Training your teams in data literacy and automation management is equally crucial. Businesses that pair Repmold with lean manufacturing and quality-assurance frameworks often achieve the fastest ROI.

Repmold and SEO / Content Marketing Potential

Interestingly, Repmold isn’t just transforming factories; it’s also becoming a powerful keyword in content marketing. Companies that document their innovation journeys using Repmold-related terms boost brand visibility and establish topical authority.

Creating educational content around Repmold applications positions businesses as forward-thinking leaders in the Industry 4.0 conversation.

Conclusion

Repmold technology symbolizes more than manufacturing efficiency; it represents the fusion of human creativity and machine intelligence. By uniting data, design, and precision, it paves the way for products that are smarter, greener, and more responsive to consumer needs.

Whether you’re an engineer, entrepreneur, or designer, embracing Repmold isn’t just a technical upgrade; it’s an invitation to participate in the next industrial revolution. The molds of the future are no longer static; they learn, evolve, and inspire.

Read More Informative Information At Mypasokey